Poli-5000 Finish

Poli-5000 is a completely in-house process, performed and overseen by Porter Corp.

Steps include:

•Eight-direction shot blasting of steel to near white condition

•Wash and iron phosphate treatment

•Special epoxy primer powder coat base

•Super Durable TGIC powder top coat

•Baking and curing

•Inspection and packaging

Why Poli-5000?

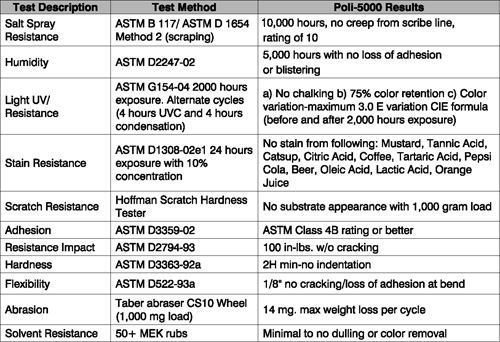

•Superior performance results over traditional powder coat

•Reduced overall cost and a better finish than field painting over factory applied red oxide primers

•No VOC’s with Poli-5000

•More environmentally friendly than liquid paint, ecoat primer, and zinc rich primer systems

•Reliable in-house inspection of all parts

•Upgrade from ‘standard’ to Super Durable TGIC provides superior color and gloss retention as well as corrosion resistance

•No need for clear top coats (that make touch-up blotchy) when using Super Durable TGIC

•Large offering of 30 standard smooth colors and 10 textured colors

Poligon Alternate Finishes

Prime Coat Only for Field Painting. When prime painting-only is requested, Poligon provides a superior job by first shot blasting then priming with a special powder-gray powder coat. This system is highly preferred over the hand wiping with rags and red oxide primer systems found elsewhere.

Hot Dip Galvanizing is a simple, long-accepted method of protecting steel from rust. It works best on plain sheets, basic tubes and other uncomplicated parts, resulting in a rough, spangled silver finish. It provides the best corrosion protection in salt-air conditions. Hot Dip Galvanizing is recommended for use in conjunction with field painting